W fender is designed for use in extreme conditions and to absorb excessive bumps and knocks. W Fenders are made for the most extreme operating conditions. W-Fender is one of the most successful rubber fenders for tugs in the world today.

The grooves on the top of the W-Shape Rubber Fenders offer an additional grip and low pressure while pushing. With the help of its two flexible legs, the design of the W rubber fenders also allows an easy installation even with a large or small radius by means of guide rods.

W Rubber Fender Applications

Ocean-going tugs

Icebreakers

Large harbor tugs – M fender, Tug fender

Bridge and pile protection

W Rubber Fender Installation:

W rubber fenders are relatively not hard to install.

Their attachment is often performed with the help of fixing pins that pass through the standard holes. W fenders are offered in different lengths and can be cut at a specified angle. If the fenders have to be longer than one meter an additional opening for a support strip can be added.

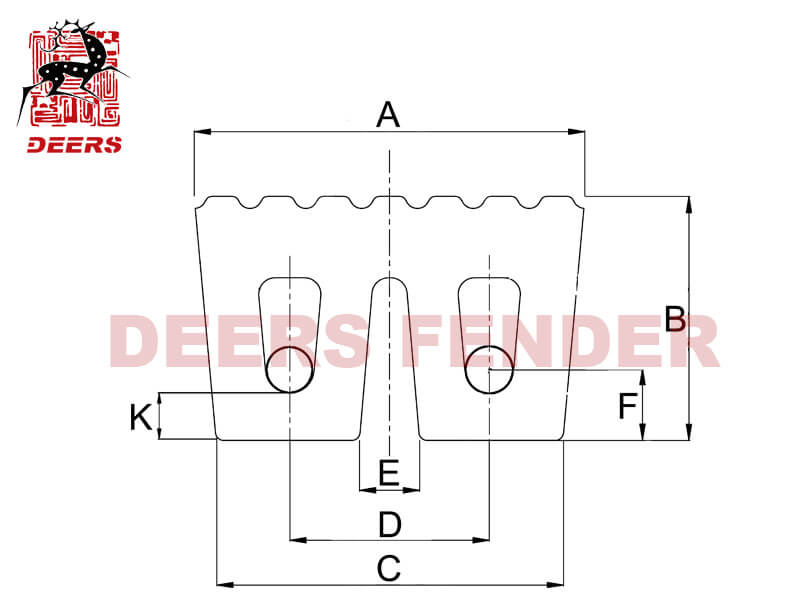

W Rubber Fender Specification:

| Type | A | B | C | D | E | F | K |

| W32-20 | 320 | 200 | 280 | 180 | 100 | 67 | 50 |

| W40-25 | 400 | 250 | 350 | 220 | 110 | 75 | 55 |

| W48-30 | 480 | 300 | 426 | 269 | 135 | 90 | 65 |

| W50-45 | 500 | 450 | 420 | 255 | 90 | 100 | 75 |

View videos about our marine rubber fender production:

View testing videos about our marine fenders:

Armored Floating Hose Pressure Testing