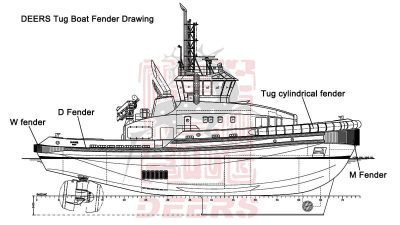

Tug Boat Fender

Tug boat fender is mainly used for harbor tugboats, installed on the bow, side and stern of the ship for jacking, pushing, leaning and towing. The use of integral manufacturing, with good overall product performance, high quality and easy installation.Tugboat rubber fenders are installed on tug boats and work longer and under extreme conditions. There are mainly three types of fenders, each type serving a particular application.

2.Side beltings

• D fenders

• Keyhole Fender

If you have any needs, please do not hesitate to contact us, we will give you an answer immediately.

1.Tug Cylindrical Fender

Tug cylindrical fenders have a wide range dimension and length, due to they can be curved in a suitable length, they are often used as the primary pushing fenders on the bow or stern of most type tug boats.

(Image of the installation and use of the tug boat fender from an Australian customer)

Features

• Simple design and economic

• Reasonable structure, practical

• Any lengths

Applications

• Tug boat

• Workboat

• Flatboat

Installation

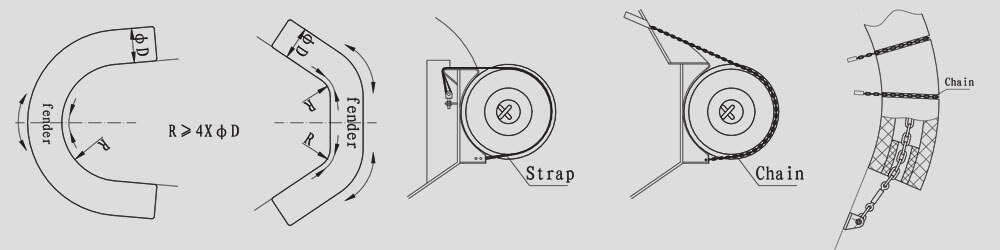

Smaller fenders (OD≤500mm)are usually fixed by a longitudinal chain through the bore of the fender, connected to the hull by turnbuckles tensioning the chain. Larger fenders often use supplementary chains or straps around the fenders.

Tug Cylindrical fenders are made in straight lengths but can be pulled around the bow of the stern radius. The outside of the fender will be pulled, inside will be compressed. the outsides are easily teared by sharp materials. To avoid damage, have to pay attention on the curve diameter R=4XΦD.

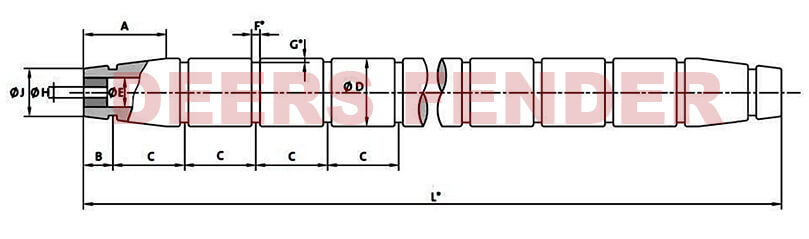

Specifications

| ØD | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| L | 2-13 meters in one section or joined for longer lengths | ||||||||||

| A | 150 | 200 | 225 | 250 | 300 | 350 | 350 | 350 | 350 | 350 | 350 |

| B(max) | 530 | 570 | 600 | 630 | 670 | 730 | 800 | 860 | 930 | 1000 | 1060 |

| C | 500 | 500 | 700 | 800 | 800 | 900 | 900 | 1000 | 1000 | 1100 | 1200 |

| E | Varies in width according to size and type of circumferential attachment | ||||||||||

| ØG | 150 | 190 | 225 | 260 | 300 | 375 | 450 | 525 | 600 | 675 | 750 |

| Ød | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| Øj | 75 | 75 | 75 | 100 | 100 | 100 | 125 | 125 | 125 | 150 | 150 |

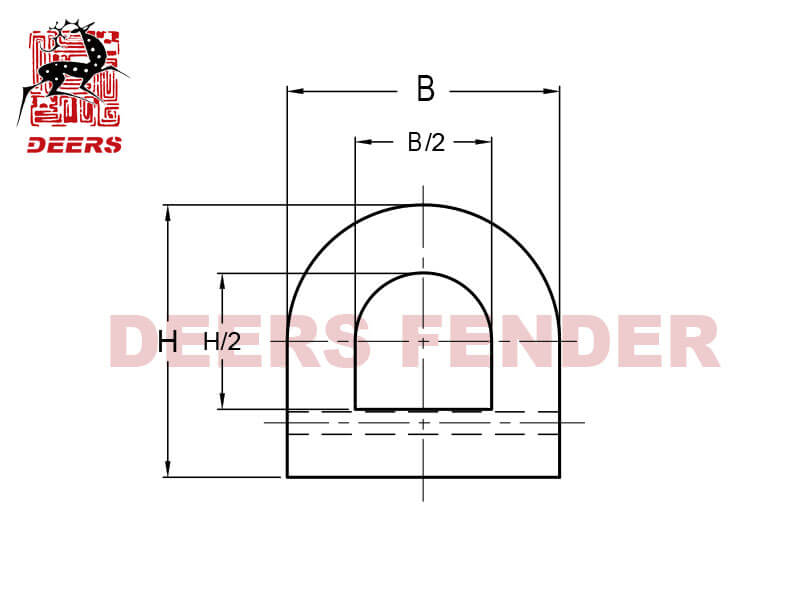

2.D Fender

Features

- All kinds of standard size

- Any length could be available

- Varies fixing methods

- Black or grey color

Applications

- Jetties and wharves for small craft

- Tugs and workboats

- Pontoon protection

- Inland waterways

- General purpose fendering

Specifications

| Model | L | A | D | d | B | B | h | P | n | Weight |

| (m) | Ø(mm) | Ø(mm) | (mm) | (mm) | (mm) | (mm) | (mm) | #Fastening Points | (kg) | |

| D200H | 1000 | 200 | 55 | 28 | 200 | 200 | 30 | 600 | 3 | 37 |

| D200H | 1500 | 150 | 55 | 28 | 200 | 200 | 30 | 600 | 3 | 56 |

| D200H | 2000 | 250 | 55 | 28 | 200 | 200 | 30 | 500 | 4 | 74 |

| D300H | 900 | 150 | 65 | 32 | 300 | 300 | 40 | 600 | 2 | 80 |

| D300H | 1000 | 200 | 65 | 32 | 300 | 300 | 40 | 600 | 2 | 67 |

| D300H | 1500 | 150 | 65 | 32 | 300 | 300 | 40 | 600 | 3 | 105 |

| D300H | 2000 | 250 | 65 | 32 | 300 | 300 | 40 | 500 | 5 | 134 |

| D300H | 1000 | 200 | 65 | 32 | 360 | 300 | 40 | 600 | 2 | 80 |

| D300H | 1500 | 150 | 65 | 32 | 360 | 300 | 40 | 600 | 3 | 120 |

| D400H | 1500 | 150 | 65 | 32 | 400 | 300 | 55 | 400 | 4 | 150 |

| D400H | 2000 | 200 | 65 | 32 | 400 | 400 | 55 | 400 | 5 | 200 |

| D500H | 1000 | 150 | 55 | 28 | 500 | 400 | 60 | 350 | 3×2 | 195 |

| D500H | 1500 | 150 | 55 | 28 | 500 | 500 | 60 | 400 | 4×2 | 298 |

| D500H | 2000 | 200 | 55 | 28 | 500 | 500 | 60 | 400 | 5×2 | 395 |

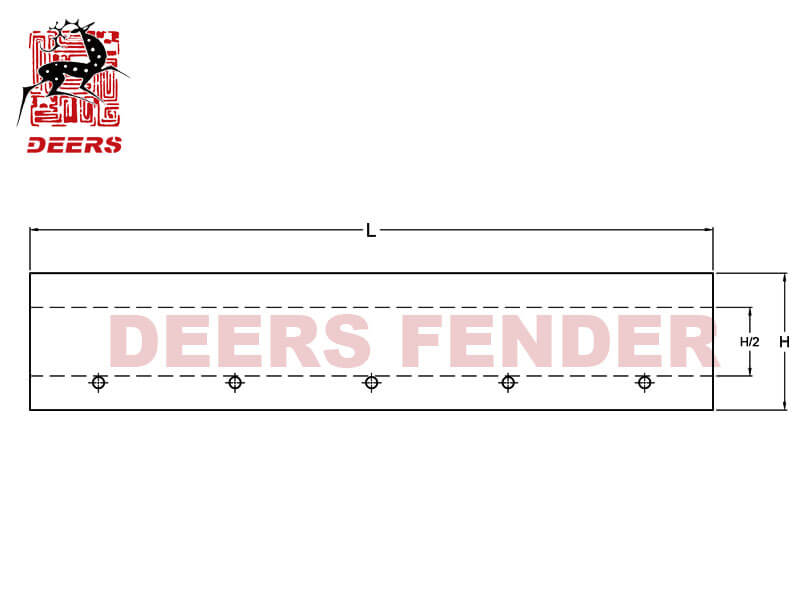

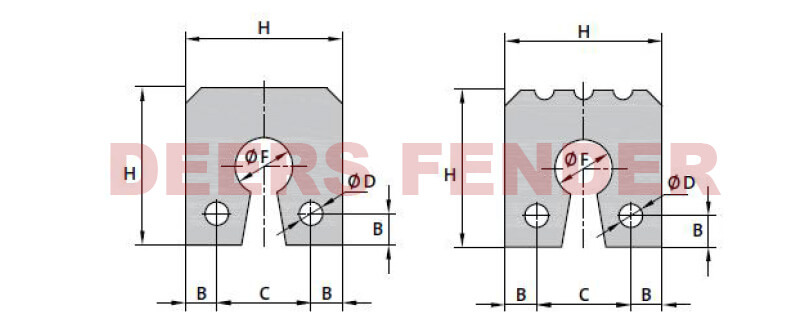

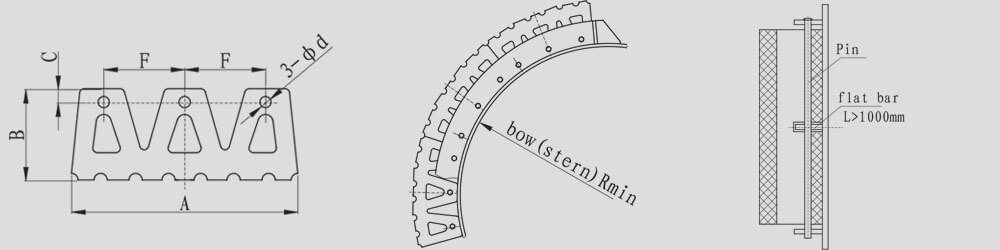

3.Keyhole Fender

Features

- Heavy-duty design Traditional, prove shape Grooved or smooth face

Specifications

| Modle | H | B | C | ΦD | ΦF | L | Φpin | Weight |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg/m) | |

| NDK200H | 200 | 35 | 130 | 28 | 90 | 2000 | 25 | 33 |

| NDK250H | 250 | 50 | 150 | 33 | 100 | 2000 | 30 | 54 |

| NDK300H | 300 | 60 | 180 | 33 | 115 | 2000 | 30 | 80 |

| NDK350H | 350 | 70 | 210 | 33 | 125 | 2000 | 30 | 114 |

If you have any needs, please do not hesitate to contact us,we will give you an answer immediately.

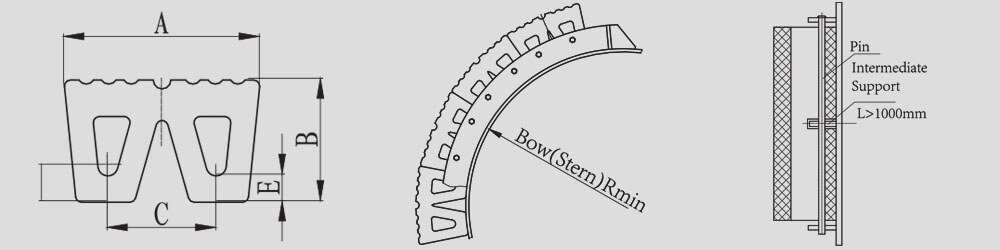

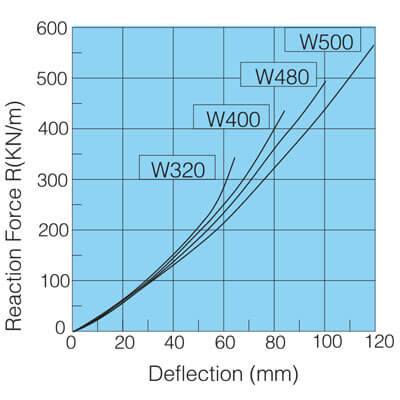

4.W Fender

Features

- Extreme-duty design

- Open bore for easy installation

- Grooved for extra grip

Applications

- Ocean-going tugs

- Icebreakers

- Large harbour tugs

Specifications

W Fender Body Specifications:

| Type | A | B | C | E | Lmax |

| W320-200 | 320 | 200 | 180 | 50 | 2000 |

| W400-250 | 400 | 250 | 220 | 55 | 2000 |

| W480-300 | 480 | 300 | 245 | 58 | 2000 |

| W500-330 | 500 | 330 | 248 | 65 | 2000 |

| W500-400 | 500 | 400 | 270 | 74 | 2000 |

Accessories:

| Pin | Flat bar | Rmin |

| ∅25 | 100*20 | 600 |

| ∅30 | 120*20 | 800 |

| ∅40 | 140*20 | 900 |

| ∅40 | 150*20 | 1000 |

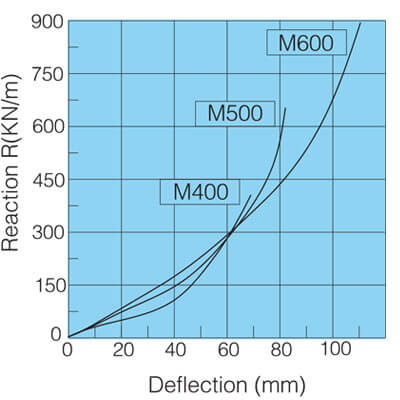

5.M Fender

Features

Applications

• Tug boat

• Workboat

• Flatboat

Specifications

M Fender Body Specifications:

| Type | A | B | C | d | F | Lmax |

| M400 | 400 | 200 | 40 | 23 | 150 | 2000 |

| M500 | 500 | 250 | 50 | 27 | 190 | 2000 |

| M600 | 600 | 300 | 60 | 33 | 230 | 2000 |

Fixings:

| Pin | Flat bar | Rmin |

| ∅20 | 100*16 | 450 |

| ∅24 | 125*20 | 550 |

| ∅30 | 150*20 | 650 |