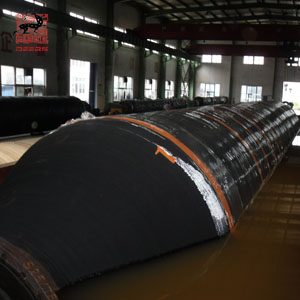

Dredge suction rubber hose is installed between the dredger and pump, and work under the negative pressure to absorb the mud. The inner diameter of the hose can be manufactured from 100mm to 1300mm. Heavy-duty big-bore suction hoses come equipped with rigid steel rings. This allows for smooth bending of the hose. It can be equipped with fixed steel flanges, loose steel flanges, or rubber flanges. Dredge suction hose either has good performance in flexibility or has high-pressure resistance and abrasive resistance. The hose has the double properties of bearing both positive and negative pressure. It can also in place of steel pipe.

Suction hoses are available as spiral type or separate ring type. And the suction hose can be divided into armored suction hose and ceramic suction hose, which have great abrasion performance. Meanwhile, the large diameter suction hose is easy to be connected with the pipeline to reduce the oscillation caused by the waves to make sure smooth flowing in the pipeline.

Product Application:

1.Corrugated hose for suction and discharge service

2.Required by industry, building, and agriculture for overhead irrigation systems

3.For tank truck use.

4.Mining

- suction hose with steel flange

- suction hose with loose steel flange

- suction hose with rubber flange

Suction Hose Specification:

| ID | Working Pressure(Mpa) | Length(m) | Pipe Wall Thickness(mm) | |

| mm | T(mm) | |||

| 250 | ±2 | 60mm mercury column

Max vac 650mm high |

1~3 | 31-32 |

| 300 | ±2 | 1~3 | 34-37 | |

| 414 | ±2 | 1~3 | 35-37 | |

| 560 | ±3 | 2~3 | 40-45 | |

| 600 | ±3 | 2~3 | 40-45 | |

| 700 | ±3 | 2~3 | 40-45 | |

| 800 | ±4 | 2~3 | 50-52 | |

| 900 | ±4 | 2~3 | 55-58 | |

View the suction hose testing videos :

Dredge hose production

We have semiautomatic 10 production lines, Mold core will be twined with rubber. Wear Layer has a color indications to remind you of the wear pattern of the hose. The outer cover layer is rubber. The cover layer will be twined with a pressing cloth. Delivering the dredge hose to vulcanizing tank makes sure the hose is durable. After the finish the hose, it will be packed with PE film or blue nylon fabric and deliver to the port of loading.

View production videos about our dredging hose:

Dredge hose testing

We have our own testing equipment to process the vacuum pressure test in our workshop. And the testing pressure can reach -0.8 bar. After the vacuum-pressure test, the hose has no change. We will do the bending test, water pressure test, diameter test before delivering to our customers.

- bending testing-1

- bending testing-2

- water pressure testing-1

- water pressure testing-2

View testing videos about our dredge hose:

Dredge Hose packaging

Dredge Hose application