BASIC INFO

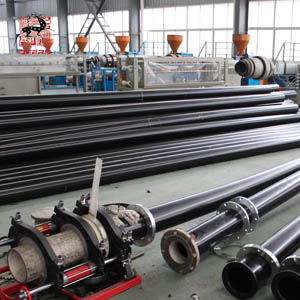

Production

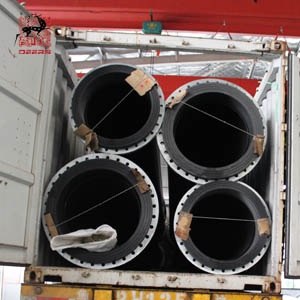

Testing Packaging Cases

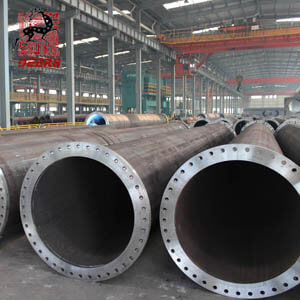

Dredge HDPE pipe is an ideal replacement of “plastic instead of steel” products, which can be used for low-pressure liquid delivery, such as water, gas, and oil.

Dredge HDPE pipe is high strength, lightweight corrosion resistance, resistance to negative pressure, easy installation, etc. And also has good low-temperature resistance and anti-ageing performance. The maximum working pressure can reach 1.6 MPa. HDPE pipes are widely used in a pipeline system.

HDPE Pipe Testing Videos:

Dredge HDPE Pipe Specification:

| Nominal outside diameter dn(mm) | Nominal wall thicknesses | ||||

| en(mm) | |||||

| PN0.6 | PN0.8 | PN1.0 | PN1.25 | PN1.6 | |

| SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | |

| 32 | – | – | – | – | 3 |

| 40 | – | – | – | – | 3.7 |

| 50 | – | – | – | – | 4.6 |

| 63 | – | – | – | 4.7 | 5.8 |

| 75 | – | – | 4.5 | 5.6 | 6.8 |

| 90 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 |

| 125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.1 | 15 | 18.7 | 23.2 | 28.6 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

| 630 | 24.1 | 30 | 37.4 | 46.3 | 57.2 |

| 710 | 27.2 | 33.9 | 42.1 | 52.2 | 63.6 |

| 800 | 30.6 | 38.1 | 47.4 | 58.8 | 72.7 |

| 900 | 34.4 | 42.9 | 53.3 | 66.2 | 81.8 |

| 1000 | 38.2 | 47.7 | 59.3 | 73.5 | – |

| 1200 | 46.2 | 57.1 | 70.6 | – | – |

View production videos about our dredging hose: