Fender panels are important parts of the marine fender units on high-performance systems. By distributing reaction forces they provide low hull pressures and cope with large tidal variations. They play an important role in protecting vessels. They are designed to allow expected shear forces induced by the vessel with its belting traveling along the outer face at higher speeds. Fender panels reduce snagging risk.

The type of the structure of fender panel

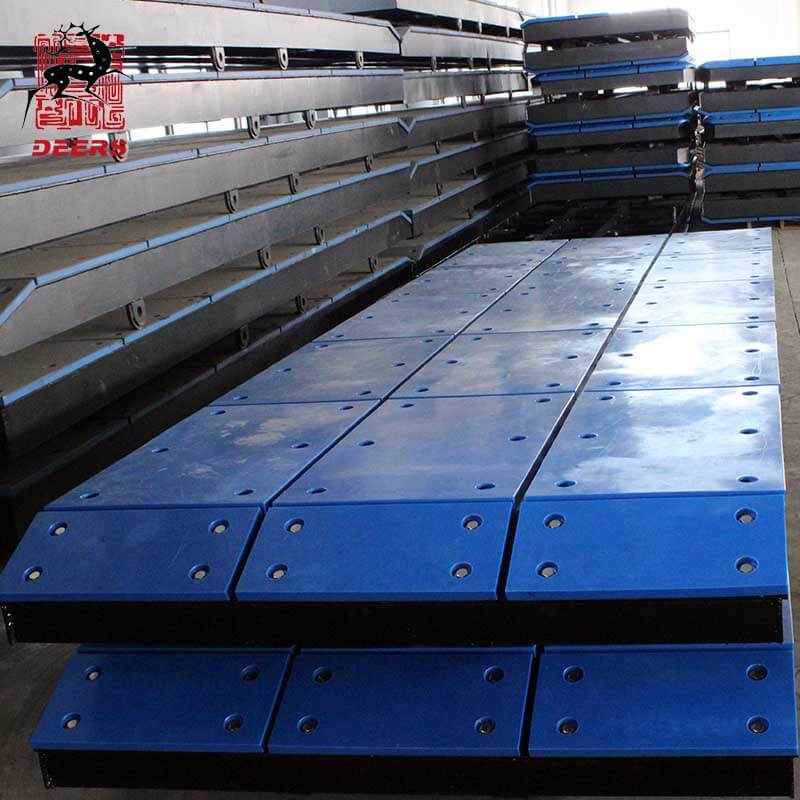

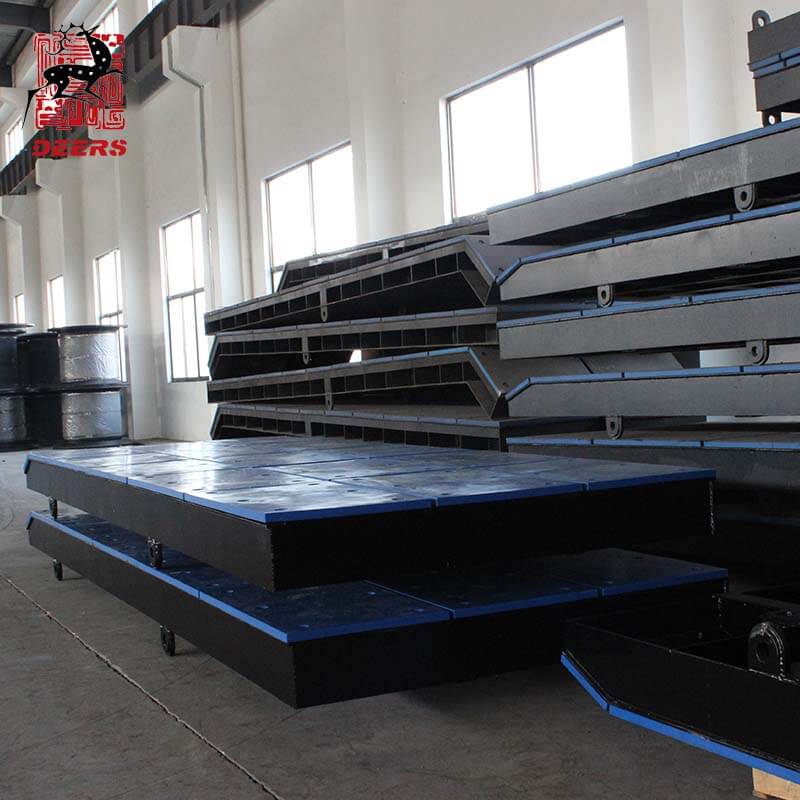

There are two types: open type and closed type. Regarding the open type, it is consists of steel pad, H steel, and across steel. The closed type is consists of steel pad, back steel, and H steel.

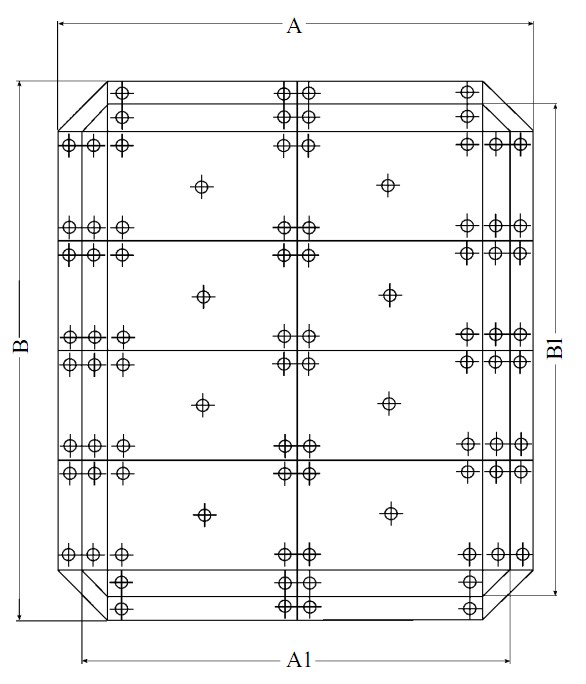

The determination of the dimension of the structure of the fender panel :

The following requirement should be met in the design:

P=∑R/ A1B1≤Py(Where P = Hull Pressure)

P= The sum of maximum reaction force of all fender (KN)

A1 = Valid width of front panel (m)

B1= Valid length of front panel (m)

Py= Hull allowable surface pressure (KN/m2)

Therefore if the allowable surface is known, the dimension of the front panel can be determined.

Specification & Design should consider below:

Hull pressures and tidal range

Lead-in bevels and chamfers

Bending moment and shear

Local buckling

Limit state load factors

Steel grade, material request

Permissible stresses

Weld sizes and types

Rubber fender connections

UHMW-PE attachment

Chain connections

Lifting points

Paint systems

Corrosion allowance

Maintenance and service life