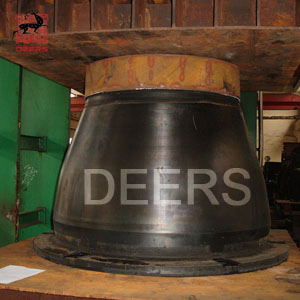

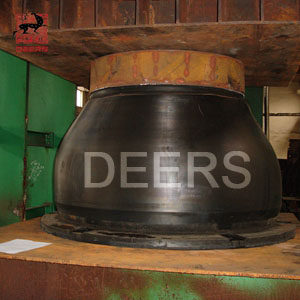

Cone rubber fender is an optimized design. It can endure server shear force and increase deflection, high-energy absorption and longer service life.

Cone fender is the latest generation of cell fender, with optimal performance and efficiency. The conical body shape makes cone fenders very stable, even at large compression angles, and provides excellent shear strength.

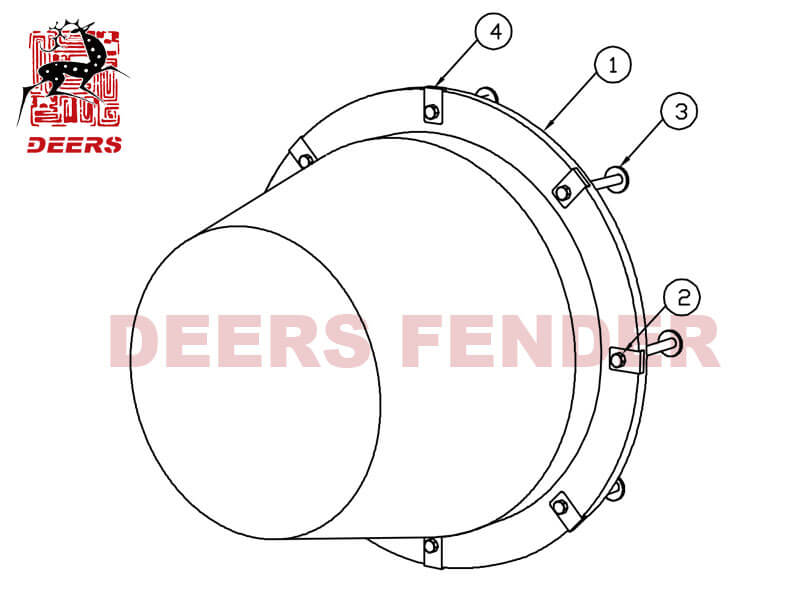

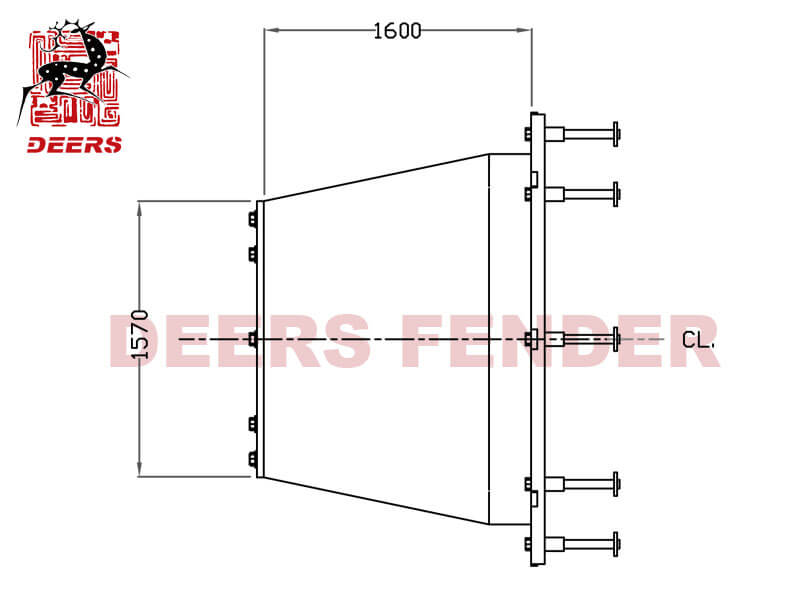

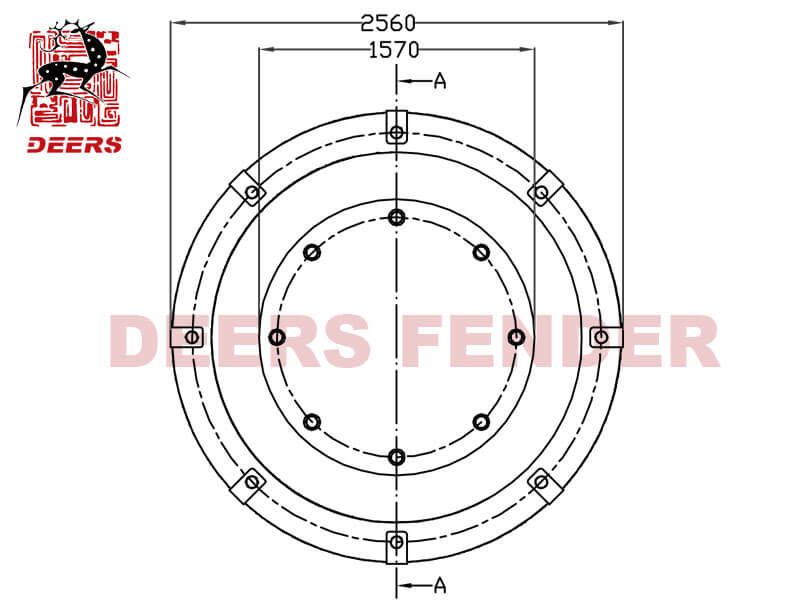

Cone Rubber Fender : Cone1600

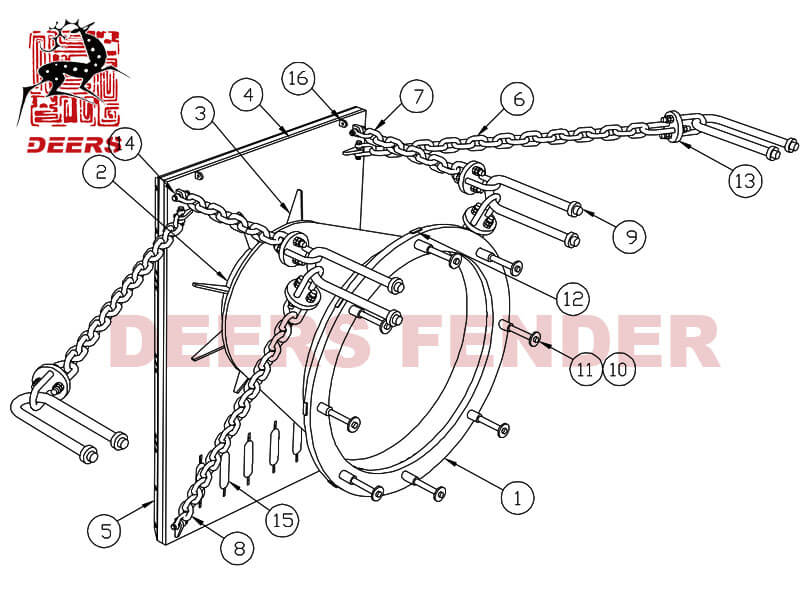

- 3D View

- Elevation

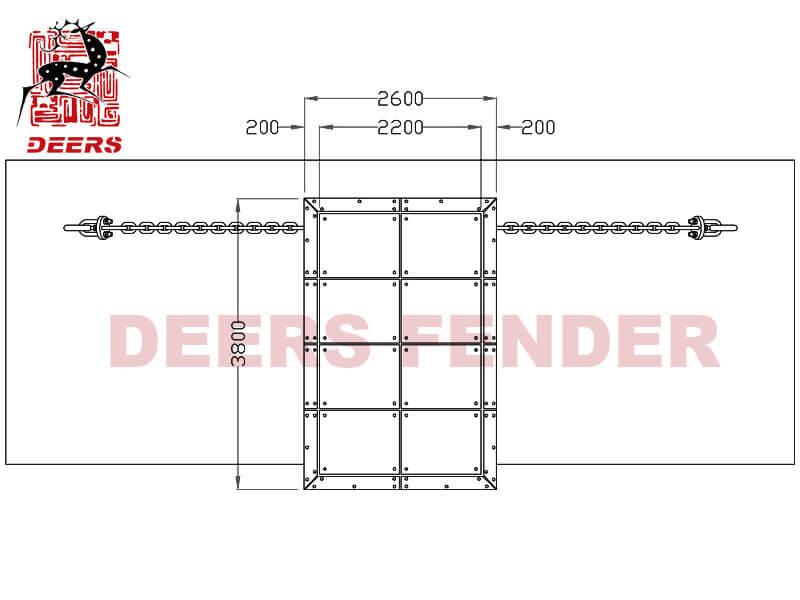

- Front View

| No | ITEM | Specification(mm) | Material | Qty |

| 1 | Cone Rubber Fender | 2560Dia,1600H | Rubber | 1 |

| 2 | Bolt | M48 | A36 Galvanized | 8 |

| 3 | Nut&Foot Rod | M48&480L | A36 Galvanized | 8 |

| 4 | Steel Washer | 139L×165B×10Thick | A36 Galvanized | 8 |

| 5 | Bolt | M48 | A36 Galvanized | 8 |

| 6 | Steel Washer | 92φ×10Thick | A36 Galvanized | 8 |

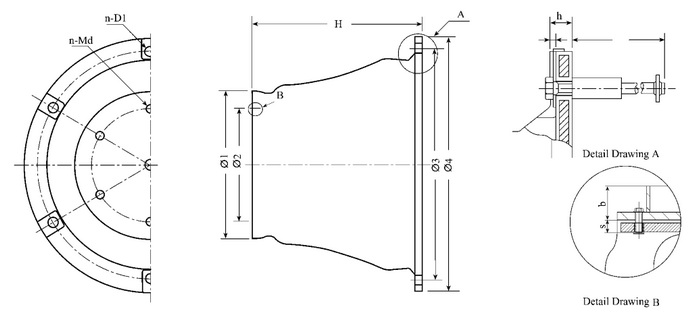

Specifications

| Types | Main Dimensions (mm) | |||||||||||

| H | h | Φ1 | Φ2 | Φ3 | Φ4 | n | D1 | Md | a | b | s | |

| CONE500 | 500 | 25 | 425 | 325 | 675 | 750 | 4 | 30 | M24 | 4 | 75~95 | 36 |

| CONE600 | 600 | 27 | 510 | 390 | 810 | 900 | 6 | 30 | M24 | 5 | 90~110 | 40 |

| CONE700 | 700 | 32 | 595 | 455 | 945 | 1050 | 6 | 38 | M30 | 6 | 105~125 | 40 |

| CONE800 | 800 | 36 | 680 | 520 | 1080 | 1200 | 6 | 44 | M36 | 7 | 120~140 | 52 |

| CONE900 | 900 | 41 | 765 | 585 | 1215 | 1350 | 6 | 44 | M36 | 8 | 135~155 | 55 |

| CONE1000 | 1000 | 45 | 850 | 650 | 1350 | 1500 | 6 | 56 | M42 | 8 | 150~170 | 65 |

| CONE1100 | 1100 | 50 | 935 | 715 | 1485 | 1650 | 6 | 50 | M42 | 8 | 165~185 | 65 |

| CONE1150 | 1150 | 52 | 998 | 750 | 1550 | 1725 | 6 | 56 | M42 | 10 | 170~195 | 70 |

| CONE1200 | 1200 | 54 | 1020 | 780 | 1620 | 1800 | 8 | 50 | M42 | 10 | 180~210 | 75 |

| CONE1300 | 1300 | 59 | 1105 | 845 | 1755 | 1950 | 8 | 60 | M48 | 11 | 195~225 | 75 |

| CONE1400 | 1400 | 66 | 1190 | 930 | 1890 | 2100 | 8 | 60 | M48 | 12 | 210~235 | 70~80 |

| CONE1600 | 1600 | 72 | 1360 | 1060 | 2160 | 2400 | 8 | 70 | M48 | 14 | 270~280 | 70~80 |

| CONE1800 | 1800 | 78 | 1530 | 1190 | 2430 | 2700 | 10 | 76 | M56 | 16 | 270~290 | 75~90 |

Cone Rubber Fender Installation

- Front view

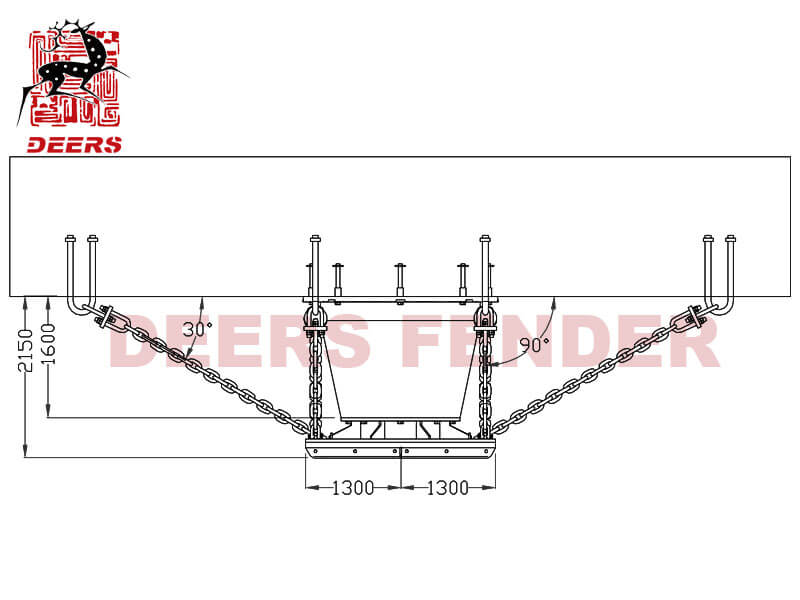

- Vertical View

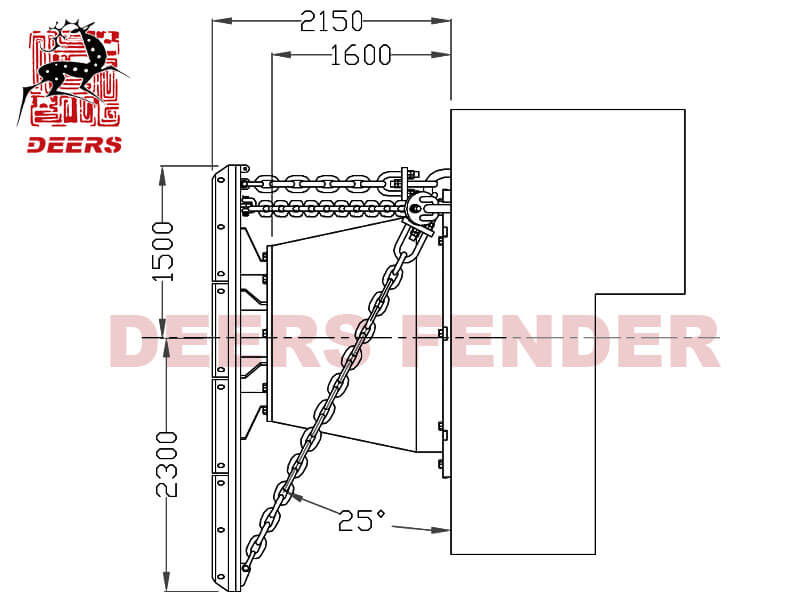

- Side View

View testing videos about our cone fender:

Cone fender has the best performance compared to other fenders.

Firstly, according to ordered or required cone fenders by clients, our engineer will make a strict and necessary formula of materials, including natural rubber, black carbon, fillings and others. Then mix all the materials together with the rubber mixer machine.

Secondly, deal with and adjust suitable mould of cone fender as the client’s specification. Then put the mixed rubber into this mould. Fill the full space of this mould with the mixed rubber material.

After the close, the mould put the whole mould into the vulcanizing tanker.

View production videos about our marine fenders:

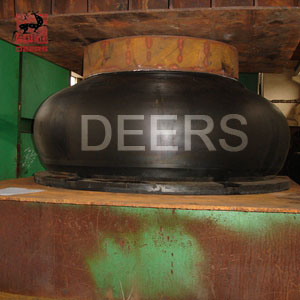

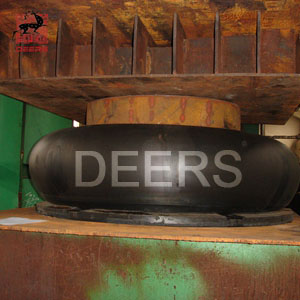

We Nanjing Deers Industrial Co., Ltd make compress testing of cone fender for our customers. Pressing the fender by compressor to simulate ship berthing. Based on spot check, every order of our cone fender will be tested before delivery.

View testing videos about our rubber fenders:

Armored Floating Hose Pressure Testing

Super Cell Rubber Fender Compress Testing

Cylindrical Rubber Fender Compress Testing