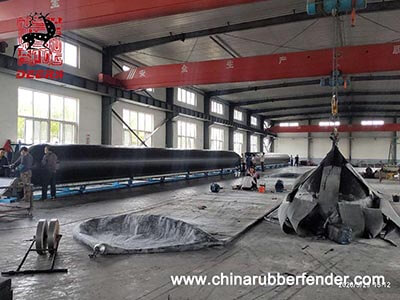

Marine ship airbags for launching applications & maintenance

Introduction of ship airbags

Ship airbags are used wildly in many shipyards for ship launching and hauling out the heavy lifting, and ship salvage. The application of marine airbags is less restricted by space, does not require large-scale machinery and equipment, and has no special requirements for the environment in which marine airbags are used. Therefore, it can shorten the engineering cycle, reduce construction costs, and save a lot of money. Marine airbags have the characteristics of safety, efficiency, environmental protection, flexibility, etc. The sizes can be customized according to requirements.

Application field of ship launching airbag

ship launching and hauling out:

After more than 20 years of practice, the launching process of airbags has developed from flat-bottomed ships weighing tens of tons to large ships with tens of thousands of tons. The practice has proved that the airbag launching process is safe and reliable.

Heavy lifting:

Ship launching rubber airbag is widely used in the lifting, transportation, launching, and other fields of caisson in port construction, as well as component displacement and launching.

ship salvage:

Ship airbags can generate large buoyancy and strong load-bearing capacity and are now widely used in the rescue of stranded ships and other buoyancy and salvage fields

Ship launching Airbag maintenance

Ship airbags storage:

1. When the ship airbags are not used for a long time, it should be washed and dried, filled with talcum powder on the outside, and placed in a dry, cool, and ventilated place indoors.

2. The ship airbags should be stretched out and placed flat, not stacked, and no heavy objects should be stacked on the airbag.

3. The place where the ship airbags are stored should be far away from heat sources.

4. The ship airbags cannot be in contact with acid, alkali, grease, and organic solvents.

Ship airbags packaging and transportation:

The packaging, transportation, and storage of ship airbags should follow the following standards:

1.Packaging

After folding, it is bundled and packed with a plastic woven bag.

2.Transportation

During short-distance transportation, ship airbags should be hoisted, lifted, and rolled in an inflated state. Towing on the ground is strictly prohibited.

Ship airbags should be folded and fixed on a pallet during long-distance transportation, with cushions underneath and wrapping with the stretch film on the outside.

Ship airbags repair

The damage forms of ship airbags can generally be divided into longitudinal cracks (cracks extending along the length of the airbag), transverse cracks (cracks extending in the circumferential direction), and nail holes (including disc-shaped damages within 10cm in diameter).

The operation steps are as follows: Delineate the repair range as the boundary of the polished surface. The repair range should extend to the cracks, and do not miss any hidden injuries. The expansion range depends on the airbag model and damage range. Usually, the 3-layer is 18-20cm; the 4-layer is 20-22cm; the 5-layer is 22-24cm; and the 6-layer is 24-26cm.

Laying of rubber cord with longitudinal cracks

1. Polish and repair part of the surface until the fiber thread is exposed, but do not damage the fiber thread.

2. For longer cracks, first, use the cord to sew. The stitch hole position is about 2 to 3 cm away from the crack, and the stitch distance is about 10 cm.

3. Clean the surface of the part to be repaired with gasoline and let it dry.

4. Apply a layer of glue. The glue is prepared by soaking raw rubber in gasoline. The weight ratio of raw rubber to gasoline is usually 1:5, and the first layer should be slightly thinner (the weight ratio of raw rubber to gasoline can be 1:8). After the first layer of glue is dried, apply a thicker glue and dry.

5. Seal the crack with a raw rubber strip with a thickness of 1mm and a width of 1cm larger than the crack.

6. Brush the gasoline and let it dry.

7. For longitudinal cracks, first, apply a layer of rubberized cord cloth with a width of about 10cm perpendicular to the crack direction. For transverse cracks and nail holes, step (10) can be performed directly.

8. Brush with gasoline and let dry.

9. Lay a layer of the rubberized cord fabric parallel to the longitudinal direction. The overlap area around the crack should be greater than 5cm, and the surrounding area should be cut into rounded corners

10. Brush with gasoline and let it dry.

11. Lay a layer of hanging rubber cord diagonally. The direction of the cords should be the same as the oblique cords (or reinforcement fibers) in the bag wall. The surrounding overlap area should be 1cm larger than the previous layer of rubber curtain fabric, and the surrounding area should be cut into rounded corners

12. Brush the gasoline and let it dry.