Which type rubber fender is best for Your Choice?

Date:2025-02-12

Rubber fenders are essential for protecting docks, ships, and harbor infrastructure. Choosing the right rubber fender is crucial to prevent damage, reduce maintenance costs, and ensure the safety of docking operations. Here are some key factors to consider when choosing rubber fenders.

Dock Type & Structure

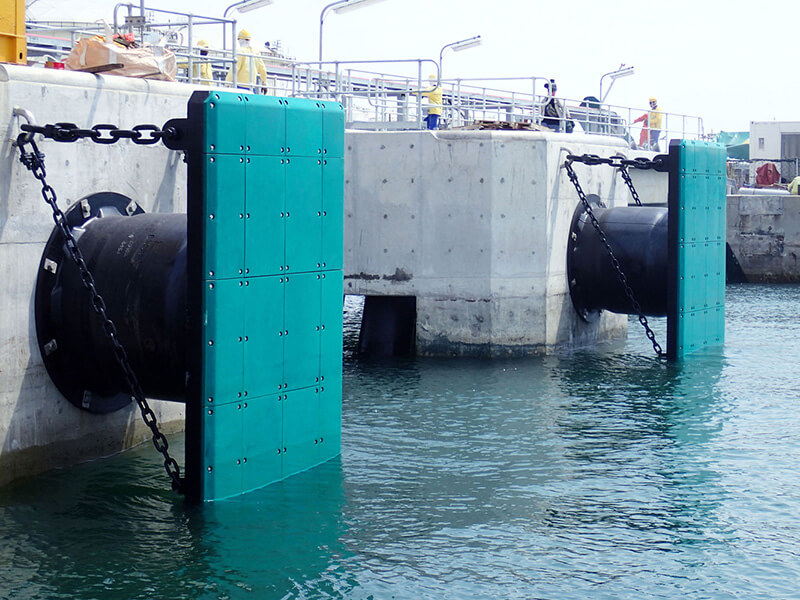

The type of dock plays an important role in determining which fender is best suited. Fixed docks, such as those made of concrete or steel, often require heavy-duty fenders like cell orcone fenders to absorb strong impacts. In contrast, floating docks work well with cylindrical or D-type fenders, which provide flexibility and moderate protection.

Vessel Size & Frequency of Use

The size and weight of the vessels docking at the port are important factors. Large cargo ships, oil tankers, and ferries exert significant impact forces and require fenders with high energy absorption, such as cone or cell fenders. Smaller boats, such as fishing vessels and recreational yachts, can be sufficiently protected with D-type or arch fenders. Additionally, docks that experience frequent berthing should use durable, long-lasting fenders to minimize wear and maintenance.

Environmental Conditions

The location of the dock determines the environmental challenges that fenders must withstand. If the dock is exposed to strong waves, tidal fluctuations, or extreme weather conditions, the fenders should be highly resilient. Harbors with significant tidal variations may require fenders that can accommodate different water levels, such as pneumatic fenders. In coastal areas with high UV exposure and saltwater corrosion, selecting fenders made from UV-resistant and anti-corrosive materials is essential for long-term performance.

Durability & Maintenance Requirements

Different types of rubber fenders require varying levels of maintenance. Solid rubber fenders, such as cell fenders, are highly durable and require minimal upkeep. In contrast, pneumatic fenders need regular air pressure checks to ensure they function properly, and foam-filled fenders may require periodic inspection for leaks. Choosing a fender that balances durability with easy maintenance can reduce operational costs over time.

Choosing the right rubber fender for your dock depends on various factors. For small docks and marinas, D-type fenders are a simple and cost-effective solution that provides sufficient protection for smaller boats. For medium to large docks with moderate vessel traffic, cylindrical fenders are a good option because they offer higher energy absorption while remaining relatively easy to install.

For large ports and high-impact areas, cone fenders are the best choice due to their superior performance and long lifespan. These fenders are ideal for container terminals, cargo ship docks, and oil tanker berths, where impact forces are significant. For docks exposed to rough environmental conditions, arch fenders provide exceptional wear resistance and are suitable for ferry terminals and industrial ports.

If your dock requires high flexibility and mobility, pneumatic or foam-filled fenders are a practical option, especially for offshore applications and temporary docking situations. However, these types of fenders require regular maintenance to ensure proper functionality.

Ultimately, selecting the best rubber fender depends on a careful evaluation of your dock’s specific needs. It is recommended to consult with us to ensure the best choice for long-term performance and cost-effectiveness. We Nanjing Deers can design and manufacture rubber fenders according to your project, if have any questions, weclome to leave a message, and we are online 24 hours a day.

Next: A Batch of Dredging Equipment on the way to United States

RELATED

- Types of pneumatic rubber fenders you should know

- 800H cell rubber fenders fly to Saudi Arabia

- Difference between Gross Tonnage, Net Tonnage, and Deadweight Tonnage

- Portugal Tender – Northern Fishing Port Maintenance Dredging

- ID750 dredging hoses and bow floaters for TSHD were delivered

- New shipment of ID500 discharge rubber hoses for dredging

- Effective Ship Anchoring: Key Steps for Stability and Safety

- Sweden Tender – Quay front reinforcement & rubber fenders replacement at Norrköping harbor